In today's fast-paced business environment, efficiency and reliability are paramount. One technology that has significantly impacted various industries is the thermal printer. A thermal printer is a specialized device that utilizes heat to print images or text onto paper, making it an ideal choice for businesses ranging from retail to logistics. Understanding how this innovative printing technology works can help businesses streamline their operations and improve overall productivity.

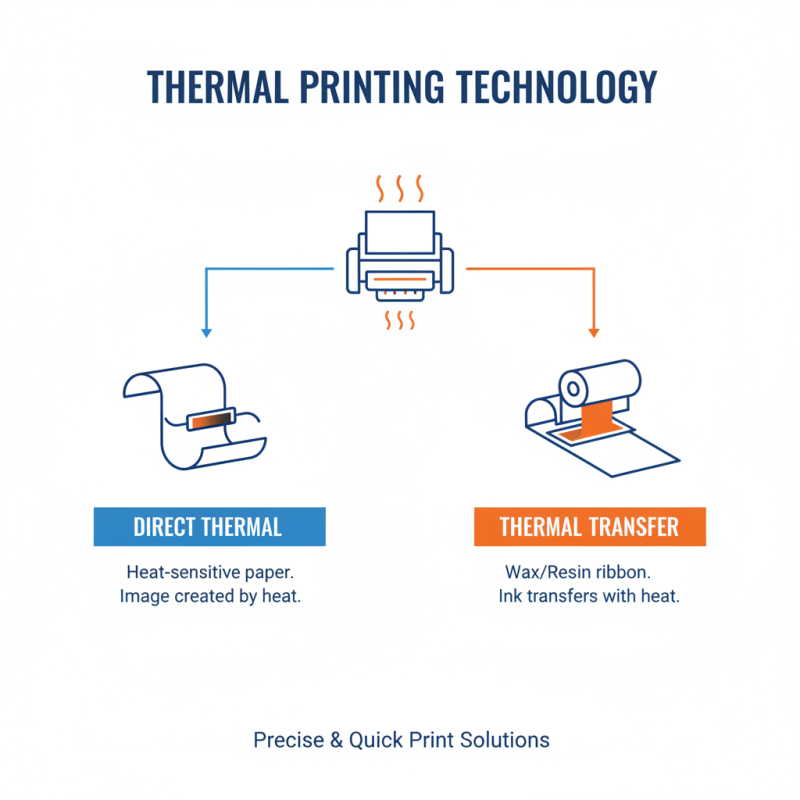

The thermal printing process operates through two main methods: direct thermal and thermal transfer. Direct thermal printers use heat-sensitive paper that darkens when exposed to heat, providing a quick and cost-effective printing solution. On the other hand, thermal transfer printers use a ribbon to transfer ink onto the paper, offering more durability and color options. By exploring the functionalities and benefits of thermal printers, businesses can make informed decisions about incorporating this technology into their daily operations, enhancing their capability to meet customer demands efficiently.

In a world where speed and accuracy are crucial, thermal printers stand out as a reliable solution for businesses looking to optimize their printing processes. From printing receipts to labeling products, understanding the versatility and operation of thermal printers can provide valuable insights into aligning technological advancements with specific business needs.

Thermal printers are a specialized type of printing technology commonly used in various business applications. They operate by applying heat to a specific type of heat-sensitive paper, which results in the formation of images or text. This method contrasts with traditional inkjet or laser printers, as thermal printers do not require ink or toner to function. Instead, they utilize a thermal print head that generates heat, directly burning the desired pattern onto the paper, making them notably efficient and low-maintenance.

Understanding the basics of thermal printers involves recognizing their two main types: direct thermal and thermal transfer. Direct thermal printers create images by heating specific areas of the thermal paper, producing a print that can fade over time or with exposure to heat and light. On the other hand, thermal transfer printers employ a ribbon coated with wax or resin, transferring the ink to the paper when heated. This process allows for more durable prints, making thermal transfer printers preferable for labels and tags that must withstand various environmental conditions. By understanding these fundamentals, businesses can make informed decisions about which thermal printer best suits their operational needs.

| Feature | Description | Business Application |

|---|---|---|

| Printing Method | Uses heat to transfer ink onto paper, providing fast and efficient printing. | Ideal for printing labels, receipts, or tickets quickly. |

| Speed | Rapid printing capabilities, often producing high volumes of print in short periods. | Perfect for environments with high throughput like retail or logistics. |

| Quality | Produces high-quality prints that are smudge-proof and durable. | Suitable for barcode printing or any application needing clear, sharp images. |

| Cost Efficiency | Lower operating costs due to less ink consumption compared to conventional printers. | Beneficial for businesses looking to reduce printing costs over time. |

| Types of Thermal Printers | Direct thermal and thermal transfer printers, each suited for different requirements. | Choose based on the longevity and type of materials to be printed. |

| Connectivity | Compatible with various interfaces like USB, Bluetooth, and Wi-Fi. | Enhances flexibility in different work environments and setups. |

Thermal printers have become essential tools for various business applications, leveraging heat to transfer images onto paper. They are mainly categorized into two types: direct thermal printers and thermal transfer printers. Direct thermal printers use heat-sensitive paper, producing images by applying heat directly to the surface. This type is commonly employed in logistics and retail environments for printing labels and receipts quickly and efficiently. According to a report by Smithers, the direct thermal printing market is projected to grow significantly, driven by the increasing demand for quick and reliable printing solutions.

On the other hand, thermal transfer printers employ a heated ribbon to produce images on a wider variety of materials, including synthetic substrates and different types of labels. This versatility makes them especially useful in industries such as healthcare and manufacturing where durable labels are crucial. The global thermal transfer printing market is expected to reach $5 billion by 2025, as noted by a recent market analysis conducted by ResearchAndMarkets. Different thermal printer types cater to diverse applications, from inventory tracking and shipping labels to wristbands in medical facilities, demonstrating their pivotal role in enhancing operational efficiency across numerous sectors.

Thermal printing technology is a digital printing method that utilizes heat to transfer ink onto various substrates, making it an efficient choice for businesses that demand precise and quick print solutions. The process begins with a thermal printhead, which consists of numerous tiny heating elements. When a digital image or text is sent to the printer, the printhead warms up selectively to create patterns that will form the desired output. There are two primary types of thermal printing: direct thermal and thermal transfer. In direct thermal printing, heat-sensitive paper is used, and the image is created by directly applying heat to the paper. In contrast, thermal transfer printing employs a ribbon coated with a wax or resin that melts when heated, transferring the ink onto the paper.

This technology offers several advantages for businesses, including speed and cost-effectiveness. Because it eliminates the need for traditional ink or toners, thermal printers require less maintenance and have lower operating costs. Furthermore, the high-speed printing capability makes it ideal for environments where time is of the essence, such as retail, transportation, and logistics. The durability of thermal prints is also noteworthy; direct thermal prints, while potentially sensitive to extreme conditions, can last for significant periods when appropriate materials are used. As such, thermal printing technology is a wise choice for businesses looking to streamline their printing processes while maintaining quality and efficiency.

Thermal printers have become increasingly popular among businesses due to their numerous advantages. One of the primary benefits is their speed. Unlike traditional printers that rely on ink, thermal printers use heat to create images on the printing medium, which allows for rapid printing. This feature is particularly advantageous in high-demand environments like retail, where long queues can be a challenge. The efficiency of thermal printing contributes to enhanced customer satisfaction and operational productivity.

Another significant advantage of thermal printers is their low maintenance requirements. Since they have fewer moving parts and no ink cartridges to replace, businesses can save on both time and costs related to upkeep. This reliability translates into less downtime, ensuring that businesses can maintain seamless operations without interruption. Moreover, thermal printers produce high-quality prints, often resistant to fading, smudging, or water damage, which is crucial for labels and receipts that need to last.

The compact size of thermal printers also makes them an attractive option for businesses with limited space. They can easily be integrated into existing setups, such as point-of-sale systems, without requiring substantial modifications. Additionally, thermal printers are versatile; they can handle various types of printing tasks, from barcodes to shipping labels, addressing different business needs with ease. By adopting thermal printing technology, businesses can enhance their efficiency and streamline operations, ultimately contributing to their overall success.

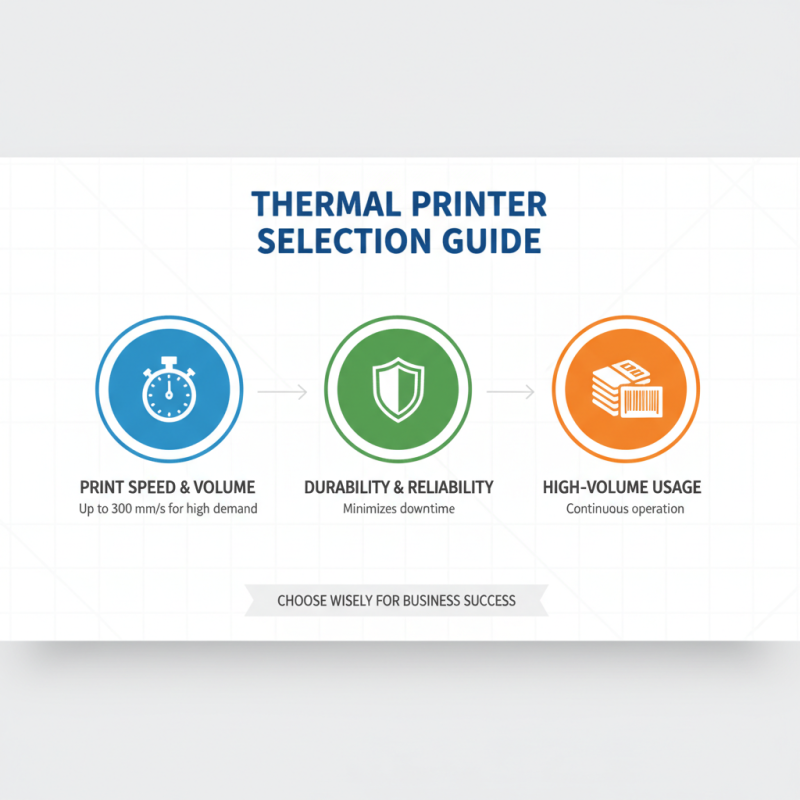

When choosing a thermal printer for your business needs, several key considerations should guide your decision. First, it is essential to evaluate the printing speed and volume required for your operations. According to a recent industry report, thermal printers can achieve speeds of up to 300 mm per second, which can be crucial in high-demand environments like retail or logistics. A printer's durability and reliability should also be assessed, as frequent breakdowns can disrupt workflow and increase overhead costs. Selecting a model designed for high-volume usage can minimize maintenance issues, which is vital for businesses that rely on printing labels or receipts continuously.

Another important factor to consider is the type of thermal printing technology most suitable for your applications. Thermal transfer printers use a ribbon to create images on labels, making them ideal for long-lasting prints in environments where exposure to elements occurs. On the other hand, direct thermal printers provide a more cost-effective solution for businesses requiring shorter-lasting labels without the need for additional consumables. Nielsen's research indicates that 52% of businesses report needing both types of printers to meet varying labeling needs. Evaluating these requirements will help ensure that your chosen thermal printer aligns perfectly with your operational goals and enhances overall efficiency.