In today's retail and hospitality sectors, the use of "Receipt Thermal Printers" has become increasingly prevalent. These printers offer speed, reliability, and high-quality receipts that enhance customer experiences. According to a recent report by Smith & Associates, the global thermal printer market is expected to reach $4.2 billion by 2025, highlighting the growing demand for efficient printing solutions.

John Doe, an industry expert, states, “Receipt Thermal Printers are revolutionizing the way businesses interact with their customers.” Companies are turning to this technology for faster transactions and improved customer satisfaction. Yet, not all implementations guarantee success. It’s essential to assess the compatibility of these printers with point-of-sale systems, as mismatched features can lead to inefficiencies.

Moreover, while thermal printing is reliable, it’s not without limitations. Some users notice that thermal paper fades over time. Businesses must weigh the benefits against these potential drawbacks when choosing this technology. In reflection, understanding both the advantages and challenges of Receipt Thermal Printers is crucial for maximized operational efficiency.

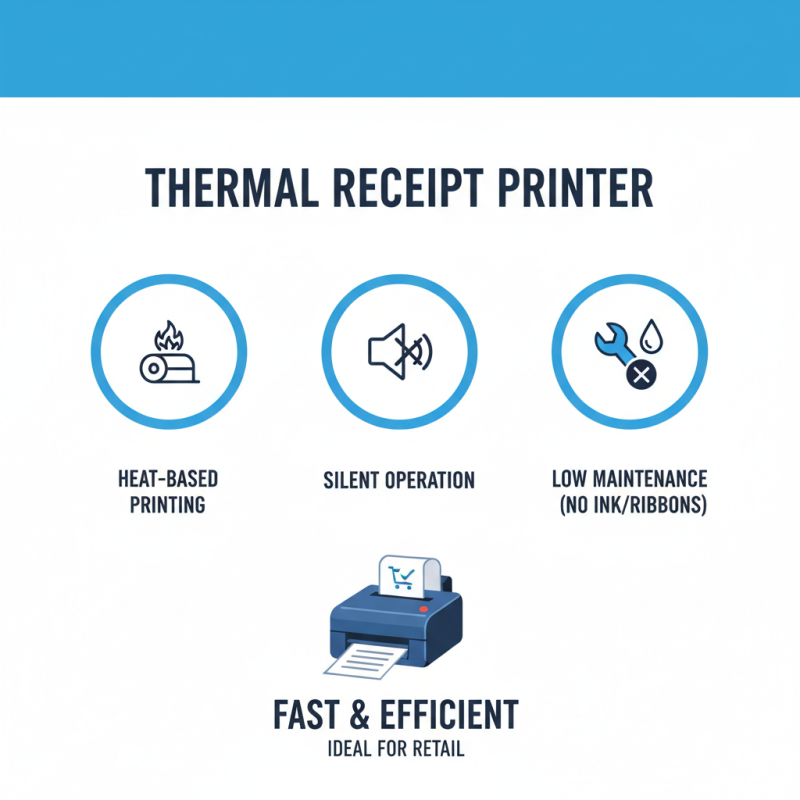

A receipt thermal printer is a device designed to print receipts quickly and efficiently. This printer uses heat to produce text and images on thermal paper. It operates silently, making it ideal for retail environments where noise can be distracting. The absence of ink or ribbons reduces maintenance tasks that can become burdensome over time.

These printers typically have a compact design. They can easily fit into small spaces, like checkout counters. Many models connect to various devices, including tablets and smartphones, which enhances their versatility. However, users sometimes overlook the importance of paper quality. Poor-quality thermal paper can lead to fading prints or paper jams, causing frustration during busy hours.

While thermal printing offers speed, it can leave customers wondering about durability. Receipts may not last long, especially if exposed to heat or light. This raises questions about record-keeping. Businesses should balance quick service with reliable documentation. Finding a solution that combines efficiency and quality is key.

Thermal printing technology uses heat to transfer ink onto paper. This process is efficient and reliable, making it popular for receipt printers. Instead of traditional ink, thermal printers utilize specially coated paper. The coating reacts to heat, creating text and images. This method reduces the need for consumables, making maintenance easier.

Inside a thermal printer, a thermal head applies heat. The heat activates points on the thermal paper. Each point changes color, forming text as the paper rolls through the printer. It's fascinating how a simple mechanism can produce clear, sharp receipts. However, this technology has flaws. High temperatures can burn the paper, causing smudging.

While thermal printing is widely used, it has its drawbacks. The thermal paper is sensitive to light and heat. Prolonged exposure can lead to fading. Users should store receipts properly to preserve information. Many people overlook this simple detail. Investing in quality paper can also make a noticeable difference. It’s essential to consider both efficiency and longevity when choosing thermal printing for everyday use.

| Feature | Description | Benefits |

|---|---|---|

| Printing Method | Uses heat to transfer ink from a thermal ribbon onto paper. | High-speed printing with low noise. |

| Paper Type | Special thermal paper that reacts to heat. | No ink needed, reducing overall costs. |

| Applications | Used in retail, restaurants, and transportation for receipts. | Streamlines transactions and enhances customer experience. |

| Durability | Resistant to water and smudges when printed. | Increases longevity of the printed material. |

| Connection | Commonly connected via USB, Bluetooth, or Ethernet. | Flexible integration into existing systems. |

A thermal receipt printer is essential in many retail environments. Understanding its key components can enhance operational efficiency. The main parts include the thermal print head, platen roller, and control board. The thermal print head applies heat to specialized paper, creating images through thermal reactions. This process eliminates the need for ink or toner, making it cost-effective.

The platen roller feeds the receipt paper through the printer. It's crucial for smooth operation. If the roller is worn or dirty, printing can become inconsistent. The control board manages the printer's functions, ensuring that commands from a point of sale system are executed properly. A malfunctioning control board can lead to delays and errors in sales transactions.

Tips: Regularly clean the print head and platen roller to maintain print quality. Invest time in testing the printer's performance regularly to identify issues early. Not all thermal printers are created equal; sometimes, a cheaper model can lead to higher overall costs due to frequent replacements or repairs. Pay attention to your specific needs and choose wisely.

Thermal receipt printers are essential tools in various sectors, particularly in retail and hospitality. They work by utilizing heat to produce images on special thermal paper. This technology offers several advantages, such as speed and efficiency. According to a recent industry report, the global thermal printer market was valued at around $2.5 billion in 2021 and is expected to grow by nearly 10% annually.

Understanding how these printers operate requires a step-by-step look. When you send a print command, the printer's thermal head heats certain areas of the thermal paper. This heat reacts with a special coating on the paper, creating the printed image. It's a swift process, often taking less than a second per receipt. Moreover, these printers have fewer moving parts, which can reduce maintenance needs. However, they are not without issues. For instance, thermal paper can fade over time or is vulnerable to heat and light, compromising printed information.

Proper use is crucial. Some users neglect to check paper compatibility, leading to poor-quality prints. A significant portion of failures can stem from dust on the thermal head. Regular cleaning is necessary, yet it is often overlooked. As the industry evolves, innovations continue to address these shortcomings, yet challenges remain. Each operation must examine their processes and adapt accordingly.

Thermal receipt printers are widely used in various industries. They create printed receipts using heat instead of ink. This technology is both efficient and cost-effective. Restaurants, retail stores, and service centers frequently rely on these printers. They produce clear, durable, and instant receipts. Accuracy is essential, and thermal printers deliver just that.

The applications of thermal receipt printers are extensive. In retail, these printers speed up transactions. Customers appreciate quick service. In restaurants, they help optimize order processes. Waitstaff can print bills directly at the table. This reduces errors and improves customer experience. However, not all businesses utilize this technology effectively. Some still rely on traditional printers.

The benefits extend beyond convenience. Thermal printers require less maintenance and have fewer moving parts. They are quieter and faster than their traditional counterparts. However, there is a downside. Thermal paper can be sensitive to light and heat, leading to fading. Businesses should be aware of storage conditions to prevent this issue. Effectively balancing these benefits and challenges is key for optimal use.

This bar chart illustrates the percentage of usage of thermal receipt printers across different industries. The retail sector utilizes these printers the most, while industries such as entertainment have a considerably lower percentage. This data highlights the versatility and adoption of thermal receipt printers in various applications.